Winemaking is a fascinating process that transforms grapes into a delicious beverage. It involves harvesting, crushing, pressing, fermentation, and aging; Proper sanitation and equipment are crucial for success.

Overview of the Winemaking Process

Winemaking involves a series of precise steps to transform grapes into wine. It begins with harvesting grapes at optimal ripeness, followed by crushing and de-stemming to release juices. Pressing extracts juice from skins, while fermentation converts sugars into alcohol. Clarification removes impurities, and aging enhances flavor complexity. Bottling is the final step, preparing the wine for storage. Sanitation and proper equipment are critical throughout. This process requires patience, as it can take weeks to months to complete. Understanding each stage ensures a successful outcome, whether crafting red, white, or sparkling wines.

Importance of Sanitation and Equipment

Sanitation is crucial in winemaking to prevent contamination from unwanted yeasts, bacteria, and molds. Properly sanitized equipment ensures a clean environment for fermentation, preserving the wine’s quality and flavor. Essential tools include crushers, presses, and fermenters, each serving specific roles in processing grapes and juice. Cleaning and sanitizing all surfaces and gear before use is non-negotiable. Using the right equipment, like food-grade plastics or stainless steel, prevents chemical reactions that could harm the wine. Regular maintenance of equipment and adherence to hygiene practices are vital for consistent, high-quality results. These steps form the foundation of a successful winemaking process.

Basic Ingredients and Their Roles

Grapes are the primary ingredient in winemaking, providing sugars, acids, and flavors. Yeast is essential for fermentation, converting sugars into alcohol. Water may be added to adjust the grape must. Acid blends enhance flavor balance, while pectic enzymes clarify the wine. Yeast nutrients and vitamins ensure healthy fermentation. Campden tablets or sulfites prevent spoilage. These ingredients work together to produce a high-quality wine, each playing a vital role in the process for complexity.

Step 1: Harvesting Grapes

Harvesting is the first step in winemaking, involving collecting ripe grapes. Timing is crucial, as sugar and acid levels determine the wine’s quality and character.

When to Harvest: Sugar and Acid Balance

Harvest timing is critical, balancing sugar and acid levels. Sugar levels determine alcohol potential, while acids influence freshness and structure. Winemakers test grapes regularly, using refractometers to measure sugar and pH meters for acidity. Optimal balance varies by grape variety and desired wine style. For crisp white wines, earlier harvest preserves acidity, while later harvests suit rich, full-bodied reds. Weather conditions, like rain or heatwaves, can alter ripening patterns, making precise timing essential. Achieving this balance ensures the wine’s flavor and aging potential, making it a pivotal decision in the winemaking process.

How to Harvest: Manual vs. Mechanical

Harvesting grapes can be done manually or mechanically, each with distinct advantages. Manual harvesting involves hand-picking grapes, ensuring only ripe bunches are selected and minimizing damage. This labor-intensive method is ideal for high-quality wines, as it preserves grape integrity. Mechanical harvesters, while faster and cost-effective, can be rough on grapes, potentially causing damage. They are often used for larger vineyards and bulk production. The choice depends on vineyard size, grape variety, and desired wine style. Manual harvesting is preferred for premium wines, while mechanical is practical for efficiency and scalability in larger operations.

Handling Grapes Post-Harvest

After harvesting, grapes must be handled carefully to preserve quality. Immediate steps include cleaning to remove dirt, leaves, and stems, followed by sorting to eliminate damaged or unripe grapes. Cooling the grapes to around 50°F (10°C) can help prevent premature fermentation and retain delicate aromas. For red wines, grapes may be left intact, while white wine grapes are often crushed immediately to release juice. Proper storage in a clean, cool environment is essential before processing. These steps ensure the grapes remain healthy and ready for the next phase of winemaking, maintaining the integrity of the fruit for optimal flavor and aroma development.

Step 2: Crushing and De-Stemming

Crushing breaks grape skins to release juice, while de-stemming removes stems to prevent bitterness. Proper equipment ensures efficient processing and maintains the high wine quality.

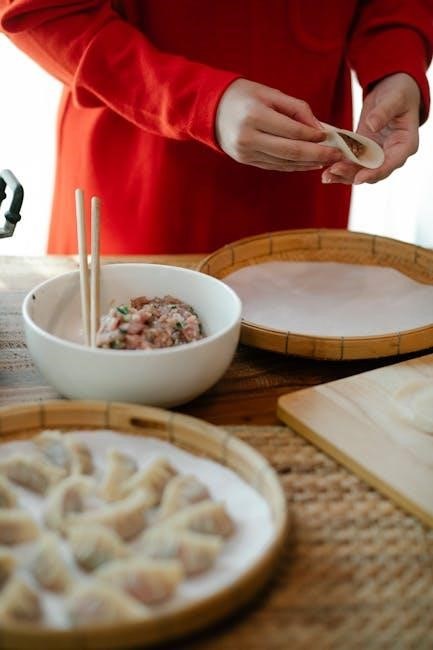

Crushing: Breaking the Grape Skins

Crushing is the initial step after harvesting, where grape skins are gently broken to release juice. This process is crucial for extracting flavors and colors from the grapes. For red wines, the skins remain in contact with the juice during fermentation, contributing to the wine’s color and tannins. For white wines, the juice is separated quickly to prevent over-extraction. Crushers, which may be manual or mechanical, are used to ensure even breaking of the skins without damaging the seeds, which can introduce unwanted bitterness into the wine.

De-Stemming: Removing Grape Stems

De-stemming is a critical step following crushing, where grape stems are removed to prevent bitterness and astringency in the wine. Stems can release unwanted tannins during fermentation, affecting the wine’s quality. Most winemakers remove about 90% of the stems, especially for red wines, as some stems can contribute positively in small quantities. De-stemming is typically done using specialized equipment that gently separates the stems from the grape skins and pulp. This process ensures cleaner fermentation and a smoother final product, preserving the delicate flavors and aromas of the grapes.

Equipment Used for Crushing and De-Stemming

The primary equipment for crushing and de-stemming grapes is the crusher-de-stemmer, which combines both processes. This machine gently breaks the grape skins and separates the stems from the pulp and juice. Modern crusher-de-stemmers are typically made of stainless steel or food-grade materials to ensure sanitation and durability. Some winemakers also use manual or mechanical harvesters to collect grapes before processing. Additional tools like sorting tables may be employed to inspect and clean grapes before crushing. Proper equipment maintenance is essential to prevent contamination and ensure efficient processing of the grapes for fermentation.

Step 3: Pressing the Grapes

Pressing extracts juice from grape skins, separating liquid from solids. This step is crucial for achieving clarity and flavor in both red and white wines.

Pressing for Red Wine

Pressing for red wine occurs after fermentation, as the skins have already imparted color and tannins. The process involves transferring the fermented must to a press, gently extracting the remaining juice. This step is crucial for achieving the desired intensity and complexity in red wines. The press separates the liquid from solids, including skins and seeds, ensuring clarity and preventing harsh tannins. Proper pressing techniques are essential to avoid over-extraction, which can lead to an unbalanced flavor profile. This step finalizes the extraction process, preparing the wine for clarification and aging.

Pressing for White Wine

Pressing for white wine typically occurs before fermentation to minimize skin contact, preserving delicate aromas and flavors. Freshly crushed white grape must is gently pressed to extract clear juice, avoiding harsh compounds. The pressing process for white wines is more immediate and precise than for reds, ensuring the juice remains pristine and free from excessive tannins. This step is critical for maintaining the wine’s crisp acidity and fruity characteristics. Proper drainage and immediate cooling of the juice prepare it for a clean, controlled fermentation process, setting the foundation for a refreshing and balanced white wine.

Pressing Techniques and Equipment

Pressing techniques vary based on wine style and equipment. Hydraulic presses are commonly used for both red and white wines, offering precise control over pressure. Pneumatic presses are gentler, ideal for delicate grapes, while traditional basket presses provide a rustic charm. Bladder presses combine efficiency with soft pressing, suitable for small-scale winemaking. The choice of equipment impacts juice quality and yield. Proper maintenance and sanitation are essential to prevent contamination. Each method ensures optimal extraction of flavors and aromas, contributing to the wine’s character and quality, with modern technologies enhancing traditional practices for consistency and craftsmanship in winemaking processes;

Step 4: Fermentation

Fermentation converts grape sugars into alcohol, driven by yeast. Monitoring progress via specific gravity and hydrometer readings ensures proper alcohol levels. Maintaining optimal temperatures is crucial for a successful process.

Alcoholic Fermentation: Converting Sugar to Alcohol

Alcoholic fermentation is the core process where yeast converts grape sugars into alcohol. Yeast ferments the must, producing ethanol and carbon dioxide. This process typically lasts 7-14 days, with temperatures controlled between 15°C for white wines and 20-25°C for reds. Monitoring with a hydrometer tracks sugar depletion and alcohol increase. Proper sanitation ensures healthy yeast activity, avoiding contamination. The fermentation vessel, often stainless steel or oak, must be sealed with an airlock to retain CO2 and prevent oxidation. Regular monitoring ensures the process progresses smoothly, resulting in a stable, flavorful wine ready for further clarification and aging.

Malolactic Fermentation: Enhancing Complexity

Malolactic fermentation (MLF) is a secondary process where lactic acid bacteria convert malic acid into lactic acid, softening the wine’s acidity and enhancing complexity. This process typically occurs after alcoholic fermentation and is more common in red wines. It adds layers of flavor, such as buttery or vanilla notes, and improves microbial stability. MLF is monitored closely, as it can vary in duration and impact. Winemakers may choose to inhibit MLF to preserve crisp acidity, especially in certain white wines. Proper conditions, like temperature and bacteria selection, are crucial for successful MLF, ensuring the wine develops desired characteristics without off-flavors.

Monitoring Fermentation Progress

Monitoring fermentation progress is crucial to ensure optimal wine development. Track temperature, as yeast thrives between 64°F-90°F. Observe airlock bubbles, indicating active fermentation. Use a hydrometer to measure specific gravity, confirming sugar-to-alcohol conversion. Regularly taste the wine to assess flavor evolution. Fermentation typically lasts 7-14 days for white wines and longer for reds. Ensure the process completes fully to avoid stuck fermentation. Monitor for visual signs, like sediment formation and clarity changes. Record observations to refine future batches. Proper monitoring prevents issues like off-flavors or spoilage, ensuring a smooth transition to clarification and aging.

Step 5: Clarification

Clarification involves removing impurities and improving wine clarity. Techniques like racking, fining, and filtration ensure stability and prepare the wine for aging and bottling.

Racking: Transferring Wine to Remove Sediment

Racking involves transferring wine from one vessel to another to separate it from sediment. This process prevents off-flavors and ensures clarity. Typically done after fermentation, racking moves clear wine to a new container, leaving behind solids. Regular racking helps stabilize the wine and enhance quality. Winemakers repeat this process until the wine remains clear and free of particles. Proper technique is essential to avoid introducing oxygen or contaminants. Racking is a critical step before bottling, ensuring the wine is polished and ready for aging. It requires patience and attention to detail to achieve optimal results.

Fining: Removing Impurities

Fining is a clarification process where substances like egg whites, gelatin, or clay are added to remove impurities. These agents attract and settle unwanted particles, improving wine clarity. It targets specific flaws, such as bitterness or off-flavors, without altering the wine’s character. Fining enhances flavor and aroma while ensuring stability. Each agent serves a purpose, from softening tannins to removing sulfur odors. Properly applied, fining polishes the wine, preparing it for bottling. Winemakers carefully choose agents to achieve desired results, ensuring the wine remains balanced and refined. This step is vital for producing high-quality, visually appealing wines.

Filtration: Ensuring Clarity and Stability

Filtration is a critical step to ensure wine clarity and stability. It removes remaining impurities, such as yeast particles or sediment, that could affect appearance or spoilage. Winemakers use methods like pad filtration or membrane filtration to achieve desired results. Filtration prevents contamination and stabilizes the wine for long-term storage. However, over-filtration can strip flavors, so careful application is essential. This process enhances visual appeal and ensures the wine remains consistent. Proper filtration techniques safeguard quality, making the wine ready for bottling and enjoyment. It’s a final polish that preserves the wine’s integrity and charm.

Step 6: Aging and Bottling

Aging enhances wine complexity, while bottling prepares it for storage. Proper preparation ensures stability and flavor preservation, marking the final step before enjoying your crafted wine.

Aging: Developing Wine Complexity

Aging is a critical phase where wine develops its complexity and character. During this period, tannins soften, and flavors mature, enhancing the wine’s balance and depth. Red wines typically age longer than whites, with some requiring years to reach optimal quality. The aging process can occur in oak barrels or stainless steel, with oak imparting additional flavors of vanilla, spice, and toast. Proper storage conditions, such as consistent cool temperatures and humidity, are essential to prevent spoilage and ensure gradual, even development. The transformation during aging elevates the wine’s profile, making it ready for bottling and eventual enjoyment.

Bottling: Preparing Wine for Storage

Bottling is the final step before wine is ready for consumption or long-term storage. It requires careful preparation to ensure clarity and stability. The wine is transferred to clean, sterilized bottles, leaving minimal headspace to prevent oxidation. Corks or screwcaps are securely sealed to protect the wine from air and contamination. Labels are applied, providing essential information about the wine. Proper storage conditions, such as a cool, dark place, are crucial for maintaining quality. Bottling marks the transition from production to enjoyment, with some wines benefiting from additional aging post-bottling.

Labeling and Packaging

Labeling and packaging are critical steps in preparing wine for market. Labels must include essential information such as the wine’s name, alcohol content, and allergen warnings. Design plays a key role in branding and attracting consumers. Packaging materials, like glass bottles or alternative options, must ensure durability and protection from light and oxygen. Sustainability is increasingly important, with many winemakers opting for eco-friendly materials. Proper sealing, such as corks or screwcaps, prevents spoilage. Effective labeling and packaging enhance the wine’s appeal and marketability, making it ready for distribution and consumption.

Specialized Winemaking Techniques

Specialized winemaking techniques include crafting sparkling and fruit wines, employing advanced fermentation methods, and optimizing temperature control for unique flavor profiles and complexity.

Making Sparkling Wine

Making sparkling wine involves a second fermentation process that captures carbon dioxide, creating the bubbles. The traditional method, known as Méthode Champenoise, ferments the wine in bottles, while the Charmat-Martinotti method uses stainless steel tanks. For bottle fermentation, a sugar and yeast mixture is added, and the wine ages on lees for at least 12 months. Riddling and disgorgement follow to remove sediment. Sparkling wines like Champagne and Prosecco undergo this process, resulting in a crisp, effervescent drink. Proper temperature control and precise timing are critical for achieving desired complexity and effervescence.

Making Fruit Wine

Making fruit wine involves fermenting fruits other than grapes, such as berries, apples, or peaches; The process begins with preparing the fruit by washing, crushing, and sometimes adding pectic enzymes to break down cell walls. The mixture is fermented with yeast, converting natural sugars into alcohol. Unlike grape wines, fruit wines often require added sugar or acid adjustments due to varying sugar and acid levels in the fruit. Fermentation is monitored with a hydrometer to track progress. After clarification and stabilization, the wine is bottled. Proper sanitation and patience are key to crafting flavorful and balanced fruit wines at home.

Advanced Winemaking Tips

Advanced winemaking techniques include cold settling to clarify juice before fermentation and using oak aging for added complexity. Monitoring fermentation with a hydrometer ensures proper sugar-to-alcohol conversion. Acid adjustments can enhance balance, while blending different varieties or batches creates unique flavor profiles. Experimenting with yeast strains can impart distinct characteristics to the wine. Regular racking and fining improve clarity and stability. Investing in quality equipment, like stainless steel fermenters, maintains consistency. Keeping detailed records helps refine techniques over time. These methods elevate craftsmanship, resulting in sophisticated and refined wines.

Quality Control and Troubleshooting

Quality control involves monitoring fermentation, checking for off-flavors, and ensuring sanitation. Common issues like stuck fermentation or contamination can be resolved with proper hygiene and timely adjustments.

Common Issues During Winemaking

Common issues in winemaking include stuck fermentation, contamination, off-flavors, and oxidation. Stuck fermentation occurs when yeast stops converting sugar to alcohol, often due to nutrient deficiencies or low temperatures. Contamination from wild yeast or bacteria can spoil the wine, producing unpleasant odors or flavors. Off-flavors arise from improper sanitation, overripe grapes, or excessive sulfur dioxide. Oxidation can lead to a loss of color and aroma, especially in white wines. Regular monitoring, proper hygiene, and timely adjustments are essential to prevent these problems and ensure a successful winemaking process.

Laboratory Testing and Adjustments

Laboratory testing is crucial for monitoring wine chemistry and ensuring quality. Key parameters include sugar levels, pH, and titratable acidity (TA). Adjustments may involve adding acid blend to balance acidity or sugar to enhance fermentation. Testing for yeast viability and nutrient levels ensures healthy fermentation. Regular analysis helps detect potential issues like off-flavors or contamination early. Proper laboratory practices guide winemakers in making informed decisions, such as adding finings or filtering for clarity. Accurate testing and timely adjustments are vital for producing consistent, high-quality wines.

Sanitation and Hygiene Practices

Sanitation is critical in winemaking to prevent contamination and spoilage. All equipment and surfaces must be thoroughly cleaned and sanitized before use. Cleaning removes dirt and residue, while sanitizing kills harmful bacteria, yeasts, and molds. Common sanitizers include bleach, hot water, and specialized wine-sanitizing products like sodium metabisulfite. Proper hygiene practices, such as washing hands and wearing clean gloves, are essential. Equipment should be sanitized regularly, especially before and after fermentation. Maintaining a sterile environment ensures healthy yeast growth and prevents unwanted microbial activity, which can ruin the wine. Regular sanitization is a cornerstone of successful winemaking.

Winemaking is a rewarding journey requiring patience and attention to detail. From harvesting to bottling, each step demands care. Experiment, learn, and enjoy the process!

Winemaking involves a series of carefully planned steps, transforming grapes into wine. The process begins with harvesting grapes at optimal ripeness, followed by crushing and de-stemming to release juices. Fermentation converts sugars into alcohol, with red wines fermented on skins for color and flavor. Pressing separates liquid from solids, and clarification removes impurities. Aging enhances complexity, and bottling prepares the wine for storage. Each step requires precision, patience, and attention to detail. The journey from vineyard to bottle demands skill and dedication, ultimately yielding a product that reflects the winemaker’s craft and the quality of the grapes.

Final Tips for Successful Winemaking

Sanitize thoroughly to prevent contamination, as cleanliness is key to avoiding spoilage. Monitor temperature during fermentation, ensuring optimal conditions for yeast activity. Use high-quality ingredients and yeast for better flavor and aroma. Regularly track progress through hydrometer readings and tastings. Be patient, as rushing the process can compromise quality. Store equipment properly to maintain hygiene and longevity. Experiment with techniques but follow proven methods for consistency. Keep detailed records to refine future batches. With dedication and attention to detail, you’ll craft exceptional wines that reflect your skill and passion.

Future Steps: Experimentation and Improvement

After mastering the basics, explore advanced techniques like oak aging or blending to enhance complexity. Experiment with new grape varieties or yeast strains to diversify your wines. Consider enrolling in workshops or joining winemaking communities to gain insights and refine your craft. Invest in better equipment, such as temperature-controlled fermenters, for precision. Track your progress by documenting each batch’s journey and analyzing results. Continuous improvement comes from learning and adapting, so embrace innovation while staying true to proven methods. The journey of winemaking is lifelong, offering endless opportunities for creativity and growth.