The 4L60E valve body is a critical component of the automatic transmission system, regulating fluid pressure and gear shifts. It houses solenoids, pressure regulators, and the manual valve, ensuring smooth operation and precise control over transmission functions. Proper maintenance and understanding of its structure are essential for optimal performance and longevity.

1.1 Overview of the 4L60E Transmission

The 4L60E is a four-speed automatic transmission widely used in General Motors vehicles, known for its durability and versatility. It is electronically controlled, featuring a lock-up torque converter for improved fuel efficiency. Designed for rear-wheel-drive applications, it is commonly found in trucks, SUVs, and performance cars. The transmission’s compact design and robust construction make it suitable for a variety of driving conditions, from daily commuting to heavy-duty towing. Its electronic controls enable smooth gear transitions and adaptive shifting based on driving habits. This transmission has become a popular choice for enthusiasts due to its reliability and potential for performance modifications.

1.2 Importance of the Valve Body in Automatic Transmissions

The valve body is the brain of an automatic transmission, directing hydraulic fluid to engage gears smoothly. It controls pressure, ensuring proper torque delivery and gear shifts. Without a functioning valve body, the transmission cannot operate efficiently, leading to poor performance and potential damage. In the 4L60E, it houses critical components like solenoids and sensors, enabling precise electronic control. Regular maintenance is essential to prevent issues and ensure longevity, making the valve body a vital component for reliable transmission function and overall vehicle performance.

Key Components of the 4L60E Valve Body

The 4L60E valve body comprises solenoids, pressure regulators, sensors, and the manual valve, each playing a crucial role in controlling fluid flow and gear shifts efficiently.

2.1 Valve Body Structure and Design

The 4L60E valve body is designed as a compact, intricate component, typically constructed from cast aluminum for durability. Its structure includes a series of passages and chambers that direct hydraulic fluid to control gear shifts. The design integrates solenoids, pressure regulators, and the manual valve, ensuring precise control over transmission operations. The valve body’s layout is engineered to minimize fluid restriction while maximizing efficiency. Its robust construction withstands high-pressure environments, making it a reliable core of the automatic transmission system. Regular maintenance is essential to ensure optimal performance and longevity.

2.2 Solenoids and Their Functions

The 4L60E valve body utilizes solenoids to regulate hydraulic fluid flow, enabling precise control over gear shifts and torque management. These electromagnetic components are activated by the transmission control module, directing fluid pressure to engage clutches and bands. Solenoids ensure smooth transitions between gears, enhancing overall transmission performance. Their proper function is vital for maintaining optimal vehicle operation. Regular inspection and maintenance of solenoids are essential to prevent transmission issues.

2.3 Pressure Regulators and Sensors

Pressure regulators in the 4L60E valve body are essential for maintaining consistent hydraulic fluid pressure, ensuring smooth gear transitions. Sensors monitor pressure levels, providing real-time data to the transmission control module. This feedback loop allows the system to adjust pressure dynamically, optimizing performance and preventing damage; Properly functioning pressure regulators and sensors are critical for avoiding issues like slipping or incorrect gear engagement. Regular maintenance, such as cleaning or replacing faulty sensors, is vital to uphold the transmission’s reliability and overall vehicle performance. These components work in harmony to ensure the valve body operates efficiently under varying driving conditions.

2.4 Manual Valve and Its Role

The manual valve in the 4L60E valve body plays a crucial role in controlling gear shifts when the driver manually selects gears, bypassing the automatic mode. Connected to the gearshift or a manual shifter, it directs hydraulic fluid to engage the desired gear. This valve ensures precise control over transmission operation, particularly in scenarios requiring driver input, such as towing or driving in hilly terrain. Its design allows for seamless interaction with the valve body, enabling smooth transitions between manual and automatic modes. Proper functioning of the manual valve is essential for maintaining driver control and overall transmission performance. Regular inspection is recommended to prevent wear and ensure reliability;

Functionality of the Manual Valve in the 4L60E

The manual valve enables driver-controlled gear shifts, directing hydraulic fluid to engage specific gears manually. It ensures precise control during towing or steep terrain, enhancing transmission responsiveness and stability.

3.1 How the Manual Valve Controls Gear Shifts

The manual valve in the 4L60E operates by mechanically redirecting hydraulic fluid to specific clutch packs or bands, engaging desired gears. When the driver selects a gear, the manual valve allocates fluid pressure to the corresponding components, ensuring precise and controlled shifts. This mechanism allows for manual override of the automatic transmission, providing better driver control during conditions like towing or descending steep inclines, where automatic shifting may not be ideal. The valve’s design ensures smooth transitions between gears, maintaining stability and preventing unnecessary wear on transmission parts.

3.2 Interaction Between the Manual Valve and Solenoids

The manual valve works in conjunction with the solenoids to regulate gear shifts seamlessly. While the manual valve controls mechanical gear selection, the solenoids manage electronic pressure regulation. The transmission control module (TCM) sends signals to the solenoids, which adjust hydraulic pressure based on driver input, such as throttle position and vehicle speed. This interaction ensures smooth transitions between gears, with the manual valve providing mechanical feedback and the solenoids fine-tuning the process. Their coordinated effort is essential for maintaining optimal transmission performance and responsiveness, blending manual and electronic controls effectively.

3.3 Hydraulic Pressure Management

The manual valve plays a crucial role in managing hydraulic pressure within the 4L60E transmission. It directs pressurized fluid to engage or disengage specific clutch packs and bands, controlling gear shifts. Hydraulic pressure is regulated through a combination of mechanical and electronic controls, ensuring precise timing and force during transitions. The valve body distributes fluid under pressure to various components, maintaining proper lubrication and torque transfer. Effective pressure management is essential for smooth, reliable gear changes, preventing slippage or abrupt shifts that could damage the transmission or compromise performance. This system relies on accurate pressure regulation to maintain optimal operational efficiency.

4L60E Valve Body Parts Diagram

The 4L60E valve body parts diagram provides a visual representation of all components, including solenoids, pressure regulators, and the manual valve, aiding in identification and maintenance.

4.1 Detailed Breakdown of the Parts

The 4L60E valve body consists of various components essential for transmission operation. The manual valve controls gear shifts, while solenoids regulate fluid pressure electronically. Pressure regulators ensure proper hydraulic flow, maintaining transmission performance. Sensors monitor system conditions, providing real-time feedback. Each part is intricately designed to work in harmony, ensuring smooth gear transitions and optimal efficiency. Understanding these components is crucial for effective maintenance and repair, as outlined in the parts diagram. Regular inspection and replacement of worn parts can prevent costly repairs and extend the transmission’s lifespan.

4.2 Identifying Key Components in the Diagram

The 4L60E valve body diagram illustrates the layout and interconnection of its components. The manual valve is prominently displayed, showcasing its role in gear control. Solenoids are labeled, highlighting their electronic functions. Pressure regulators and sensors are clearly marked, emphasizing their importance in fluid management. The diagram also outlines hydraulic fluid pathways, providing a visual guide to understanding the system’s operation. By referencing the diagram, users can locate and identify each part, aiding in maintenance, repair, and upgrades. This visual tool is essential for diagnosing issues and ensuring proper functionality of the valve body.

4.3 Understanding the Flow of Hydraulic Fluid

The hydraulic fluid in the 4L60E valve body flows through a network of channels and ports, regulated by solenoids and the manual valve. The fluid originates from the transmission pump, entering the valve body to pressurize clutch packs and bands. The manual valve directs fluid to specific gears, while solenoids fine-tune the pressure for smooth shifts. Sensors monitor fluid pressure, ensuring optimal performance. The flow is controlled by the valve body’s internal design, enabling precise gear engagement and disengagement. This system ensures efficient torque transfer and seamless shifting, critical for the transmission’s operation.

Installation Guide for the 4L60E Valve Body

Installing the 4L60E valve body requires precise tools and careful alignment. Follow step-by-step instructions to ensure proper seating and connection of hydraulic lines for optimal transmission performance.

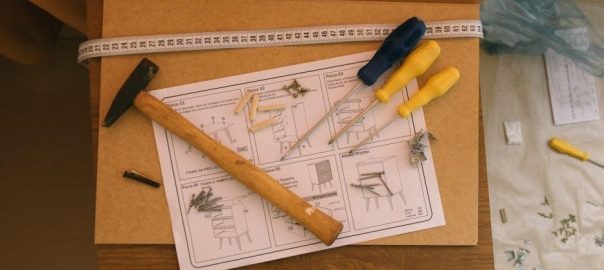

5.1 Tools and Materials Needed

To install the 4L60E valve body, you will need a torque wrench, socket set, hydraulic fluid, gaskets, seals, and a cleaning kit. Ensure all tools are compatible with your transmission type. A drain pan and protective gloves are essential for safe handling of fluids. Refer to your manual for specific torque specifications and fluid recommendations. Use high-quality materials to prevent leaks and ensure proper sealing. Properly organize all components before starting the installation to avoid misplacement or damage. Always follow safety guidelines when working with hydraulic systems and electrical components. Use genuine or OEM-approved parts for reliability and longevity.

5.2 Step-by-Step Installation Process

Begin by draining the transmission fluid and disconnecting the electrical connectors. Remove the valve body bolts and carefully lift the old unit out. Inspect the transmission case for debris and clean thoroughly. Install the new valve body, ensuring proper alignment with the case. Tighten the bolts in a star pattern to the specified torque. Reconnect the solenoid pack and electrical connectors. Refill the transmission with the recommended fluid level. Bleed the system to remove air pockets and test the transmission through all gears. Ensure smooth operation before finalizing the installation. Always refer to the manufacturer’s instructions for precise torque specifications and fluid requirements.

5.3 Common Mistakes to Avoid

- Not bleeding the hydraulic system properly, leading to air pockets and erratic shifts.

- Using incorrect torque specifications for valve body bolts, risking damage to the transmission case.

- Forgetting to clean the transmission case thoroughly, causing contamination.

- Improperly aligning the valve body with the case, leading to mechanical failure.

- Using the wrong type of transmission fluid, affecting hydraulic pressure and performance.

- Not testing the transmission thoroughly after installation, missing potential issues.

These mistakes can result in poor performance or complete system failure, emphasizing the importance of careful installation and adherence to guidelines.

Maintenance and Repair of the 4L60E Valve Body

Regular cleaning, inspection, and replacement of worn parts ensure optimal performance. Proper reassembly and testing are crucial to maintain hydraulic integrity and prevent transmission failure.

6.1 Cleaning and Inspection Procedures

Cleaning and inspecting the 4L60E valve body involves disassembling and flushing it with a solvent to remove contaminants. Use compressed air to dry components and check for wear or damage on springs, seals, and bores. Inspect electrical connectors for corrosion and ensure all ports are clear. Replace any damaged or worn parts to prevent leaks or pressure issues. Proper cleaning ensures smooth hydraulic flow and accurate gear shifts, maintaining transmission efficiency and longevity.

6.2 Replacing Worn or Damaged Parts

When replacing worn or damaged parts in the 4L60E valve body, start by identifying faulty components through inspection. Use original equipment manufacturer (OEM) or high-quality aftermarket parts to ensure compatibility and performance. Replace seals, gaskets, and worn-out valves to restore hydraulic integrity. Carefully install new solenoids, ensuring proper electrical connections. Apply the recommended torque specifications for bolts and fittings to prevent leaks. Replace the manual valve if it shows signs of wear, as it is crucial for gear control. Always follow a detailed repair manual for precise instructions to avoid further damage or transmission malfunctions.

6.3 Reassembly and Testing

After replacing worn or damaged parts, carefully reassemble the 4L60E valve body by reversing the disassembly process. Ensure all components, such as the manual valve, solenoids, and gaskets, are properly aligned and securely fastened. Use the recommended torque specifications for all bolts and fittings to avoid leaks or damage. Once reassembled, perform a hydraulic pressure test to verify functionality. Test the transmission in various modes (Park, Reverse, Neutral, Drive) to ensure smooth gear transitions and proper engagement. If equipped, use a scan tool to monitor solenoid operation and check for any error codes. Address any issues promptly before returning the vehicle to service.

Troubleshooting Common Issues

Identify common issues like leaks, erratic shifts, or solenoid malfunctions. Check hydraulic pressure, fluid levels, and electrical connections. Use diagnostic tools to isolate faults and refer to the user manual for guidance.

7.1 Symptoms of a Faulty Valve Body

Common symptoms of a faulty 4L60E valve body include slipping gears, delayed or harsh shifts, and solenoid malfunctions. You may notice fluid leaks, abnormal noises, or the transmission failing to engage properly. If left unchecked, these issues can lead to complete transmission failure, requiring costly repairs. Always monitor shifting performance and fluid levels to identify problems early. Refer to the user manual for diagnostic guidance and address issues promptly to maintain optimal transmission function and prevent further damage.

7.2 Diagnosing Solenoid Failures

Solenoid failures in the 4L60E valve body can be diagnosed by checking for erratic or harsh gear shifts and illuminated dashboard warning lights. Use a scan tool to retrieve diagnostic trouble codes, which often indicate solenoid malfunctions. Inspect the solenoid’s electrical connections for damage or corrosion. Measure solenoid resistance using a multimeter to ensure it matches the manufacturer’s specifications. Faulty solenoids may also cause inconsistent hydraulic pressure, leading to unstable gear shifts. By systematically testing these components, you can identify and address solenoid issues before they escalate, ensuring reliable transmission performance and preventing further damage to the valve body.

7.3 Addressing Pressure Regulation Problems

Pressure regulation issues in the 4L60E valve body can lead to inconsistent gear shifts, slipping, or hesitation. Start by inspecting the pressure regulator valve and associated springs for wear or damage. Use a transmission pressure gauge to measure hydraulic pressure against factory specifications. If pressure is too low or high, adjust or replace the regulator. Clean or replace clogged or dirty filter screens to ensure proper fluid flow. In severe cases, replacing the entire pressure regulator assembly may be necessary. Addressing these issues promptly prevents further damage to the valve body and ensures smooth transmission operation.

Upgrading the 4L60E Valve Body

Upgrading the 4L60E valve body enhances performance and durability. Install high-performance aftermarket components, such as reinforced solenoids and improved pressure regulators, to optimize transmission functionality and responsiveness.

8.1 Performance Enhancements

Upgrading the 4L60E valve body with performance enhancements can significantly improve transmission responsiveness and durability. High-performance solenoids and modified valve designs reduce shift times and increase torque capacity. Enhanced pressure regulators ensure consistent hydraulic pressure, improving gear engagement smoothness. These upgrades are particularly beneficial for high-performance vehicles or those subjected to heavy-duty use. Additionally, aftermarket components often include improved sealing and wear-resistant materials, minimizing the risk of leaks and premature wear. Proper installation and tuning are crucial to maximize the benefits of these performance enhancements and maintain optimal transmission functionality.

8.2 Installing Aftermarket Components

Installing aftermarket components in the 4L60E valve body requires precision and adherence to manufacturer guidelines. Begin by ensuring compatibility with your specific transmission model. Proper tools and a clean workspace are essential to avoid contamination. Follow the step-by-step instructions provided with the components, ensuring all connections are secure and aligned correctly. Testing the system post-installation is crucial to verify functionality and performance improvements. Always refer to the user manual for specific torque specifications and installation sequences to prevent damage or improper fitment. Professional assistance is recommended for those without prior experience.

8.3 Tuning the Valve Body for Optimal Performance

Tuning the 4L60E valve body involves adjusting internal components to enhance transmission performance. Calibrating the pressure regulator and solenoid settings ensures precise control over hydraulic pressure. Fine-tuning shift points and firmness can improve acceleration and drivability. Upgraded springs and seals may be installed to handle increased pressure demands. It’s crucial to follow manufacturer specifications and use specialized tools for adjustments. Testing under various driving conditions helps verify optimal performance. Regular monitoring of transmission behavior post-tuning ensures reliability and longevity of the components. Proper tuning can significantly enhance the transmission’s responsiveness and overall vehicle performance.

Safety Tips for Working with the 4L60E Valve Body

Always wear protective gear and ensure the vehicle is on level ground. Disconnect the battery to prevent electrical shocks. Handle hydraulic fluid with care, avoiding skin contact. Use jack stands for added safety and never work under a vehicle unsupported. Keep a fire extinguisher nearby and avoid smoking. Follow proper disposal methods for transmission fluid and components. Regularly inspect tools for damage to prevent accidents. Maintain a clean workspace to minimize hazards. Adhere to manufacturer guidelines for safe handling and repair procedures.

9.1 Proper Handling of Hydraulic Fluid

Always wear protective gloves and eyewear when handling hydraulic fluid. Ensure the workspace is well-ventilated to avoid inhaling fumes. Use spill containment measures to prevent environmental contamination. Dispose of used fluid and filters responsibly, following local regulations. Avoid skin contact, as hydraulic fluid can cause irritation. Store fluid in approved containers, away from heat sources and open flames. Check for leaks regularly and address them promptly. Use the correct type of ATF (Automatic Transmission Fluid) recommended for the 4L60E to maintain optimal performance and prevent damage to internal components. Keep rags handy to clean up spills immediately.

9.2 Safety Precautions During Installation

Disconnect the battery to prevent accidental starts. Use jack stands to secure the vehicle, ensuring it is on level ground. Wear protective gear, including gloves and safety glasses. Avoid over-tightening connections to prevent damage. Keep rags nearby to clean spills. Never smoked or use open flames near hydraulic fluid. Ensure proper ventilation to avoid inhaling fumes. Follow torque specifications for bolts and connectors. Avoid touching electrical components to prevent static discharge. Double-check all connections before starting the engine. Never test drive without ensuring all safety measures are in place. Always refer to the factory service manual for specific guidelines.

9.3 Preventing Damage to Electrical Components

Disconnect the battery before starting work to avoid power surges. Use an anti-static wrist strap to prevent static discharge. Keep the work area dry to avoid moisture-related damage. Handle electrical components by the connectors, not the wires, to prevent strain. Avoid bending or flexing wires excessively. Use clean, dry cloth to wipe connectors. Apply dielectric grease to prevent corrosion. Ensure all connections are secure to avoid vibration damage. Never splice wires without proper insulation. Ground yourself before touching sensitive electronics. Test components with a multimeter before installation. Follow the factory service manual for specific electrical guidelines to ensure longevity and reliability of the system;

The 4L60E valve body is a vital transmission component, ensuring smooth gear shifts and optimal performance. Proper maintenance and understanding its function are key to longevity and reliability.

10;1 Summary of Key Points

The 4L60E valve body is a central component of the transmission, controlling hydraulic pressure and gear shifts. Proper installation, maintenance, and troubleshooting are essential for optimal performance. Regular inspection and cleaning prevent wear and tear, while addressing issues like faulty solenoids or pressure imbalances ensures reliability. Upgrades and aftermarket components can enhance functionality for high-performance applications. Understanding the valve body’s structure and operation is crucial for DIY repairs and professional servicing. Always follow safety guidelines when handling hydraulic fluid and electrical components. By adhering to these practices, the 4L60E valve body will provide consistent and efficient transmission operation.

10.2 Final Tips for Maintaining the 4L60E Valve Body

Regular inspection and cleaning of the valve body are essential to prevent contamination and wear. Always check hydraulic fluid levels and condition, ensuring compatibility with the system. Use high-quality replacement parts and follow proper torque specifications during reassembly. Avoid over-tightening components to prevent damage. Keep the transmission cool by maintaining proper coolant levels. Regularly update transmission control module software for optimal performance. If unsure about any procedure, consult a professional technician. Proper maintenance ensures longevity and reliable operation of the 4L60E valve body.